Transforming Wastewater Treatment for Factories in Vietnam: Your Essential Solution!

Hello everyone, working hard in Vietnam as always,

I am Jung Min-cheol, the team manager in charge of Korean companies at Kizuna, a leader in the ready-built factory complex located in Long An Province, Vietnam.

Working at Kizuna, I've realized there's a lot of information that would be beneficial for you to know.

While I can't disclose any internal secrets, I intend to share some useful information regarding factory operations.

Let's start with the somewhat sensitive topic of wastewater treatment facilities this month.

1. Wastewater Treatment in Industrial Parks (IP)

When discharging water outside in an IP, it must be of Grade A. Failure to do so can lead to a temporary shutdown of the entire IP or a hefty fine. Therefore, IPs generally have wastewater treatment facilities. The daily wastewater treatment capacity of an IP is fixed, which could potentially limit the admission of companies based on their wastewater output.

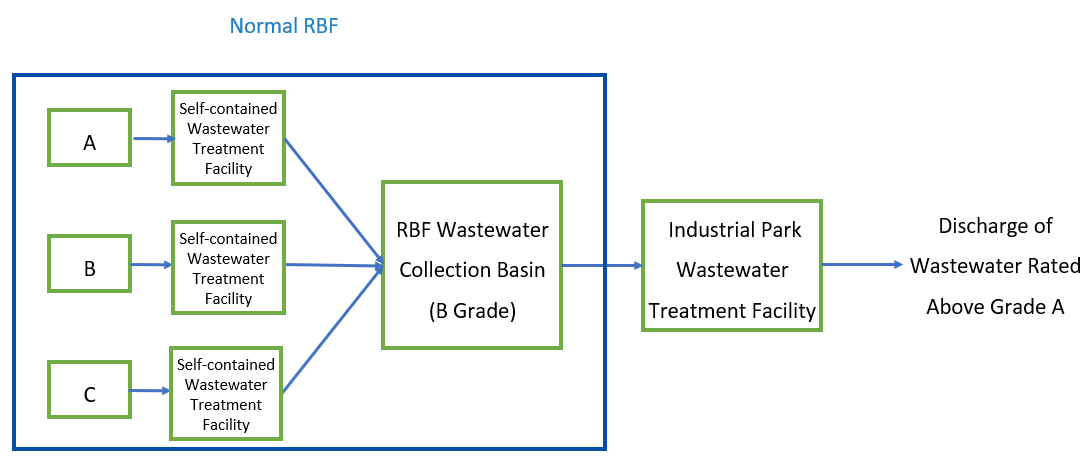

Let's delve into the standard wastewater treatment system in IPs, noting that there might be slight differences among various IPs.

Typically, factories within the IP must send Grade B wastewater to the IP's collection tank. The collected wastewater, below Grade B, is then purified to Grade A in the IP's own treatment plant before being discharged. Some IPs might treat up to Grade C wastewater (for an additional fee), but others require factories producing Grade C wastewater to have their own treatment facilities.

2. Wastewater Treatment in Ready-Built Factory Complexes (RBF)

RBF buy (technically lease, but let's say buy for simplicity) land within IPs and build factories to lease to tenants. I'll explain these concepts in more detail next time.

The wastewater treatment in RBF is not much different from that in IPs. Tenant companies in the RBF send their wastewater to the RBF collection tank, which is then sent to the IP's collection tank. Unless there's a special facility to treat Grade C wastewater, the RBF must send Grade B wastewater to the IP's collection tank. Generally, RBF do not have their own treatment facilities, so tenants must ensure that the wastewater they send to the RBF collection tank is Grade B. If Grade C wastewater is found, the entire operation of the RBF could be halted, with the responsible company bearing all consequences. Therefore, factories capable of producing Grade C wastewater must build their own treatment facilities.

Even if wastewater is treated to Grade B, additional costs arise as it needs to be treated again to Grade A by the IP.

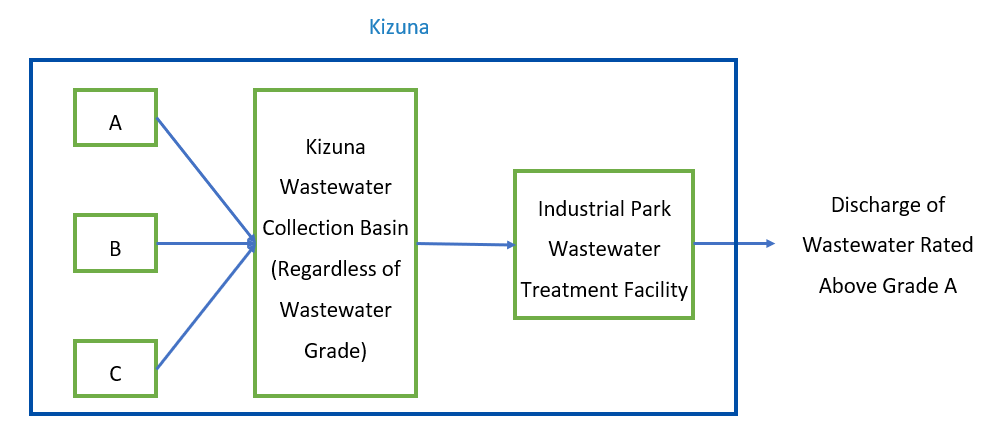

3. Special Wastewater Treatment at Kizuna

Kizuna boasts a unique wastewater treatment system, distinguishing it from other RBF. Kizuna 1 has a capacity of 150m3/day, Kizuna 2 has 250m3/day, and Kizuna 3 can treat 1,600m3/day, capable of handling even Grade C wastewater (for an additional fee). At Kizuna 3, collected wastewater is sent to its own treatment plant and purified to Grade A before being discharged directly, eliminating the need to send it to the IP, hence saving on IP wastewater treatment costs. Kizuna 1 and 2 treat Grade B wastewater and send it to the IP's collection tank.

This facility is especially crucial for food processing industries, making Kizuna a favorite among them, including the famous CJ Food in Kizuna 3.

4. How is Wastewater Graded?

Wastewater is graded based on its concentration. I've attached the criteria for Grade B wastewater for your reference.

5. Wastewater treatment facility... Can’t we just build it?

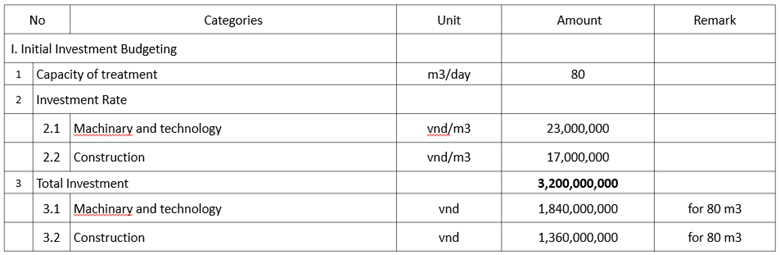

Building, operating, and maintaining a factory's own wastewater treatment facility costs more money than expected. We have secretly obtained details of the construction and operation of our own wastewater treatment facility that can treat 80m3 per day. The source is secret.

- Construction cost: Construction cost is approximately 170 million won in Korean won (equivalent 126,492USD).

You may say, “Well, it’s not even 200 million, but it’s the price of chewing gum,” but if you build it, you have to operate it and maintain it.

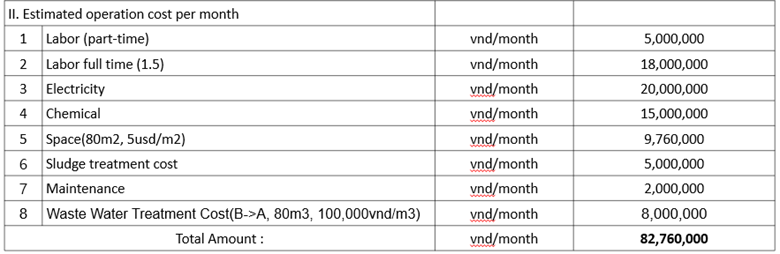

- Operation and maintenance costs (monthly): Approximately KRW 4.5 million (equivalent 3,350USD) per month is required (including labor costs, operating costs, additional space rental cost, and industrial park wastewater treatment costs).

Usually, when you sign a lease contract with the RBF, the contract lasts for about 5 years on average. Assuming that rent and labor costs do not rise, including construction costs, it will cost about 450 million won (equivalent 334,923USD). If you join our Kizuna 3, you will be able to save more than 50% over 5 years, although it may vary slightly depending on the wastewater concentration. Please contact us and we will let you know about our wastewater treatment costs.

6. Other Wastewater Treatment Methods

If it is difficult to treat wastewater in an IP or RBF, there is a way to collect the wastewater and take it outside through an outsourcing company. The cost of this method varies depending on the grade of wastewater and the location of the outsourcing company, and it is a relatively inefficient method. Since this method is not handled directly by us, we will skip the detailed explanation..

Today, I briefly talked about the wastewater treatment system. I have tried to make it as easy as possible for you to understand, and I have no doubt that you will have fully understood it.

Kizuna is always open to you.

If you would like to enter Vietnam for business or expand or relocate your business to the southern region, please contact us at any time. We will do our best to advise you.

Contact

KOR : 01076241747(Kakaotalk)

VN : 0355471731(Zalo)